Blog

Targeting Silica Dust for Improved Mine Safety

November 10, 2022

Thousands of mine workers across the United States and Canada are potentially exposed to airborne hazards such as silica dust (also known as respirable crystalline silica) every year.

Thousands of mine workers across the United States and Canada are potentially exposed to airborne hazards such as silica dust (also known as respirable crystalline silica) every year.

This can result in an elevated risk of them developing serious diseases and illnesses.

According to the National Institute for Occupational Safety and Health (NIOSH), crystalline silica is a common mineral found in such materials as soil, sand, stone, concrete, and mortar.

Cutting, sawing, grinding, drilling, and crushing stone and rock, for example, can release hazardous levels of respirable crystalline silica – tiny particles at least 100 times smaller than ordinary beach sand – into the air.

Negative Effects

Breathing in silica dust can lead to silicosis. This disease occurs when silica dust particles get trapped in lung tissue – causing scarring and inflammation, as well as reducing the lungs’ ability to take in oxygen. Damage to the lungs is permanent, progressive, debilitating, and sometimes fatal.

In addition, NIOSH says mine workers exposed to silica dust and those with silicosis are also at increased risk of tuberculosis, a contagious and potentially life-threatening infection.

Some other diseases and illnesses mine workers exposed to silica dust are at increased risk for developing:

- Autoimmune diseases (including rheumatoid arthritis, systemic lupus erythematosus, and systemic sclerosis/scleroderma),

- Chronic Obstructive Pulmonary Disease/COPD (including chronic bronchitis and emphysema),

- Kidney disease, and

- Lung cancer.

Engineering controls can be used at mines to eliminate or mitigate exposure to silica dust. Wet methods use water sprays to control dust – for example, NIOSH found a water-spray attachment on jackhammers could suppress and reduce dust exposures by 70 to 90 percent. Dry methods involve ventilation controls, such as vacuums and high-efficiency particulate air (HEPA) filters controlling dust in the air.

Administrative controls can also limit the risk of exposure to silica dust in mining workplaces. These controls include providing mine workers with proper training, supervision, and medical surveillance and monitoring; developing and distributing detailed safety plans and procedures; posting warning signs wherever applicable; and conducting regular site inspections and exposure assessments.

Personal protective equipment (PPE) may also be necessary. The Canadian Centre for Occupational Health and Safety (CCOHS) says safety goggles suitable for dust protection protect the eyes and face, while protective clothing prevents contact with the skin. Mines may also require the use of other equipment, such as personal respirators. All PPE should be properly fitted, tested, and certified.

Safety Initiatives

Governing bodies in both the United States and Canada announced in 2022 new actions aimed at further reducing the risks of silica dust exposure and other workplace hazards in mining operations.

The U.S. Department of Labor’s Mine Safety and Health Administration recently launched a new enforcement initiative to better protect mine workers from health hazards resulting from repeated overexposure to silica dust.

As part of this initiative, Mine Safety and Health Administration (MSHA) officials are conducting silica dust-related mine inspections and expanding silica sampling at mines across the country, while providing mine operators with compliance assistance and best practices to limit miners’ exposure to silica dust.

Here in Canada, Ontario’s Ministry of Labour, Immigration, Training, and Skills Development (MLITSD) and Workplace Safety North (WSN) recently announced inspectors would be conducting a province-wide ‘inspection blitz’ on hazards associated with air quality and workplace hazardous materials in underground mines – including exposure to silica dust.

As part of the campaign, inspectors are checking to ensure employers are following requirements for air quality in mines and mining plants, pits, and quarries for exposures to dust, silica, diesel emissions in underground mines, chemicals, and re-agents at workplaces.

Here to Help

Focus FS has the solutions you need to enhance and/or improve mine worker health and safety, including ways to help protect them from silica dust and its related dangers.

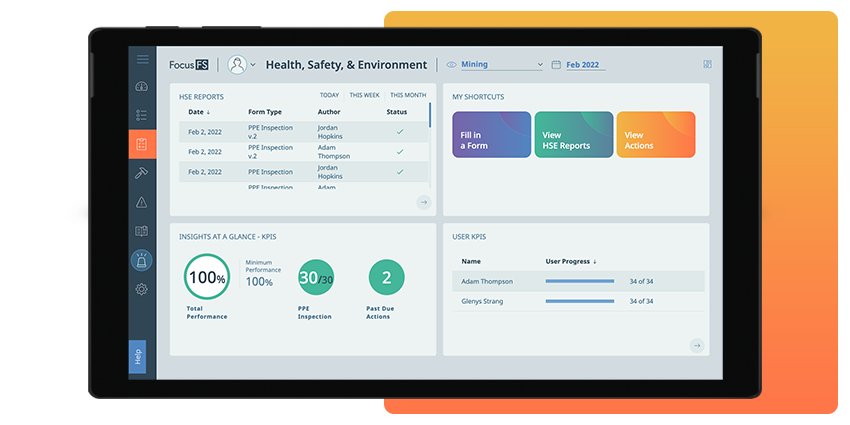

Our Asset Safety Solution allows you to create or customize digital forms for detailed equipment and asset audits, inspections, and verifications. Real-time data and analytics appear on user-friendly dashboards, providing you with the information you need to make effective decisions regarding the impact of silica dust in and around your equipment and assets.

You can also review detailed asset histories and maintenance records, oversee corrective actions to completion, and manage PPE inventory from almost anywhere with a mobile device connected to the Internet. Generate comprehensive reports that can be sent to governing bodies showing that silica dust guidelines and regulations are being followed.

With our Team Safety Solution, you can easily build or adapt digital forms for efficient HSE reporting and assessments. These completed forms can be sent directly from the field, providing you or designated personnel with immediate awareness of any health and safety issues arising from the presence (or increased levels) of silica dust. You can then manage and track any follow-up actions.

Ensure all workers receive the correct training about silica dust, including updated safety protocols and the proper usage/maintenance of PPE. Add training and certification records to digital employee profiles, then receive alerts when retraining or upgrades are required. Detailed reports can be generated for governing bodies detailing how health and safety regulations and guidelines are being met.

If an incident involving silica dust occurs at your mine, our solutions allow you to facilitate prompt investigations and reviews. Detailed data collection and deep analysis support timely internal reviews and regulatory reporting. All data is securely stored in a single location, with access available only to authorized users, for immediate or future review.

Mine workers, organization officials, and other stakeholders need to be aware of the dangers related to silica dust and work together to protect everyone against this common workplace hazard.

Focus FS can help you manage and enhance your asset and equipment management, and your worker health and safety programs, to help eliminate or lessen the dangers associated with silica dust. Contact us today for more information – use the form below to set up a meeting.

—

Sources:

Canadian Centre for Occupational Health and Safety. (n/d). OSH Answers Fact Sheets: Silica, Quartz.

Canadian Occupational Safety. (September 22, 2022). Ontario launches mining inspection blitz.

—

Let’s get started

Contact us to discuss your current strategies and find out how our solutions are improving health and safety at companies like yours.

hbspt.forms.create({

region: “na1”,

portalId: “19922270”,

formId: “681a175c-fbf0-4ce6-9b17-92c5b5967df5”

});